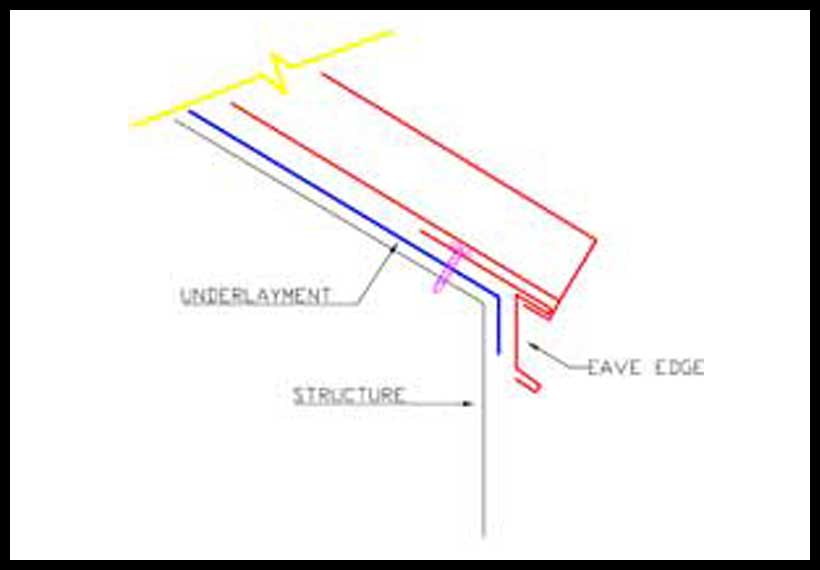

Most buildings require detailing that is customized to the specific needs of that project. The details below show some of the basic concepts of how to detail different conditions that may occur on a project. Always consult your local Ultra Seam plant for the proper detail design for your building.